“It’s all about the alcohol you put in,” he explains. “It doesn’t have to be expensive wine either, I just go by personal preference.” And just as you’re getting your head around the business leader mastering a terrific spag bol, you discover he’s also run a marathon.

Tossing in the fact as casually as the sauce on the spaghetti, he says he applies the same discipline in training for Singapore’s 2017 Standard Chartered race as he does to running his business. “When the going gets tough, pushing through is all in your mind and heart. It serves me well,” he reflects.

No matter the number of hidden talents he harbours, it’s obvious that central to Julian’s core is an acute engineering brain. Whether it’s delving into astonishing technology or the mechanics of a good meal, he’s meticulous in his thinking, always adopting a considered approach.

It’s a standard, albeit natural, tactic he’s used to help him segue from working as a research specialist for Singapore’s Ministry of Defence into excelling in sales and executive management.

Headquartered in Singapore, GVT provides manufacturing solutions and services for multiple industries, predominately the semiconductor, analytical life sciences, medical, industrial automation and electronics sectors.

With operations in Malaysia and China, the group serves some of the largest original equipment manufacturers, providing a range of engineering, assembly, testing and product life cycle management services for the manufacture of complex precision machining and sheet metal components, modular assembly with testing services and full system integration.

Components and modular assemblies for high-performance instruments are used in laboratories for environmental, food and beverage testing, pharmaceutical applications, forensics screening and clinical diagnosis.

Other customers include equipment suppliers providing solutions for semiconductor and electronics manufacturing and assembly, involved in either the front or back end of the process.

Although GVT still offers more conventional machining materials of aluminium and steel, it is one of the few companies in Singapore offering the more advanced precision ceramic and quartz machining services, which enable phenomenal accuracy. Enter that strand of hair.

“If you imagine a strand of your hair is about 30 microns, we can machine parts up to an accuracy of one micron,” Julian explains.

“We’re probably getting towards 0.5 of a micron and below, a precision moving beyond the competition.” Although he trained as a mechanical engineer, Julian’s career has been dominated more by business development roles.

He had been with Frencken for eight years and was Global Director of Sales and Marketing when he co-founded GVT with his former boss and mentor, Ricky Lee, in 2012.

Both had been involved in the precision engineering industry for more than 20 years and always entertained an ambition to set up a world-class local manufacturing company that would take the “pain” out of problematic overseas supply chains.

“Most world-class manufacturers were foreign, or at least foreign owned, and we were never able to solve supply problems outside of Asia,” he explains.

“We want to keep abreast of the latest technology, constantly upgrade our capabilities to provide world-class manufacturing. That way we can attract global customers who believe we can be better than other brands. That was always our inspiration.

“Every few years we refresh our technology road map, sharing it with our local customers who know they can be served well by us. They then share their experience with their peers in the US, Europe and Japan who have also been very impressed with what we are doing.”

As part of its commitment to focus more on analytical life sciences, GTV is a major provider to the evolving mass spectrometer industry, a market that offers the capability to test food and its origins.

An organic vegetable can cost up to four times the amount of a regular one, but do you trust it?

The company is working tirelessly to make precision parts and modules for the analytical tool small enough to be used in supermarkets and give consumers the opportunity to test on the spot whether the organic food they’re buying is genuine.

“An organic vegetable can cost up to four times the amount of a regular one, but do you trust it? How organic is organic?” Julian asks.

“Our customers are trying to miniaturise the technology for mass spectrometers to enable you to choose your organic vegetable and validate whether the claims on its labels are true. You can immediately test it to see exactly how it was grown and which soil or preservatives were used.”

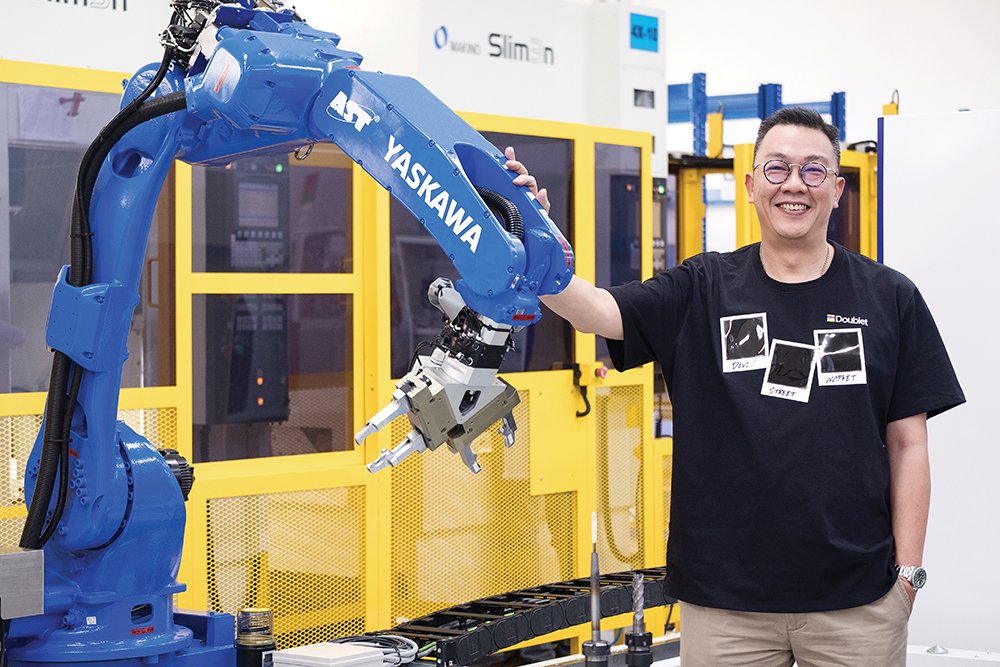

By the middle of this year, the company will have evolved into a smart factory leveraging Industry 4.0, implementing advanced technology such as automation, artificial intelligence, robotics and virtual reality to improve business and operational efficiency. It’s state-of-the-art technology developed by carefully selected employees boasting cutting-edge talent.

“We have a culture where we never stop learning,” Julian reveals. “Every year we source the polytechnics and local universities to offer internships. Of course, the challenge then is to keep them on.

“In Singapore, it’s not easy to retain university and poly grads because they usually want to go on and work for a multinational. But we find that after spending three months with us, they often want to continue working with us. It’s because we have a culture where experimentation is allowed, a winning formula we use to guide our employees out of their comfort zone. We wanted to change the perception that precision engineering is a very traditional business, so we started straight off using digital tools to attract excellent young talent.”

There’s no doubt Julian’s vibrant communication skills are also a source of encouragement for others. Acknowledging that engineers are not always “the best at communicating”, he says his many years of business development and meeting people have helped him engage more effectively.

Today, he regards himself as a “very hands-on” CEO who enjoys working together with his team, relishing in the idea that they’re manufacturing something that will help improve people’s lives.

“Whether it’s mass spec, whether it’s life sciences, it’s a very down-to-earth job,” Julian reflects. “I’ve been in this trade for many years and I still love the fact that we are part of a supply chain that ultimately produces a product that brings joy to a lot of people.”

Proudly supported by:

Astech

摄影:Yew Kwang